Computacional Fluid Dynamics – CFD

What is? What is its purpose?

Why is it such efficient tool for your Data Center?

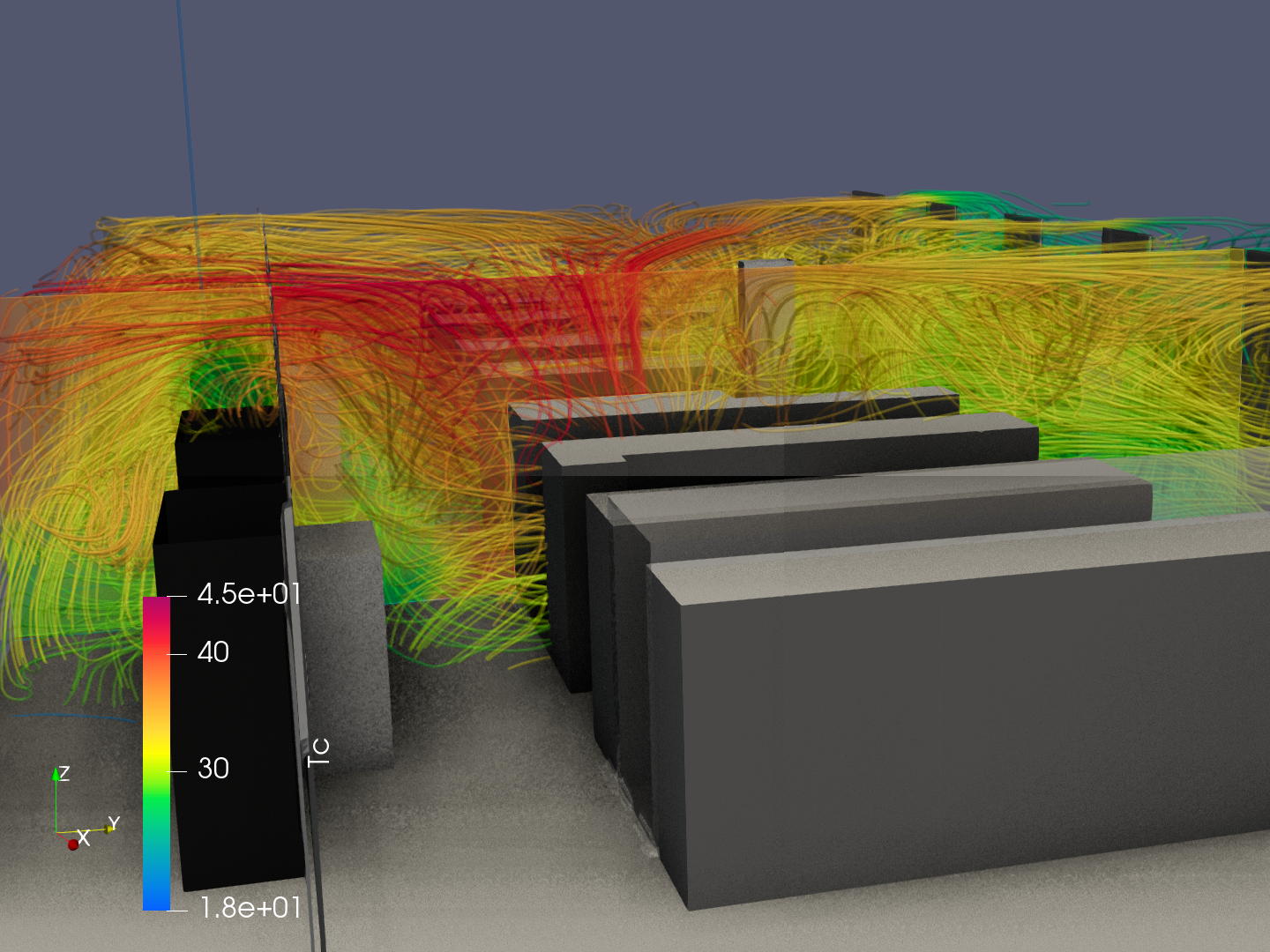

CFD, or Computational Fluid Dynamics, is a powerful engineering tool used to simulate airflow and heat transfer within complex environments — such as Data Centers, equipment enclosures, vehicles, buildings, aircraft, and more.

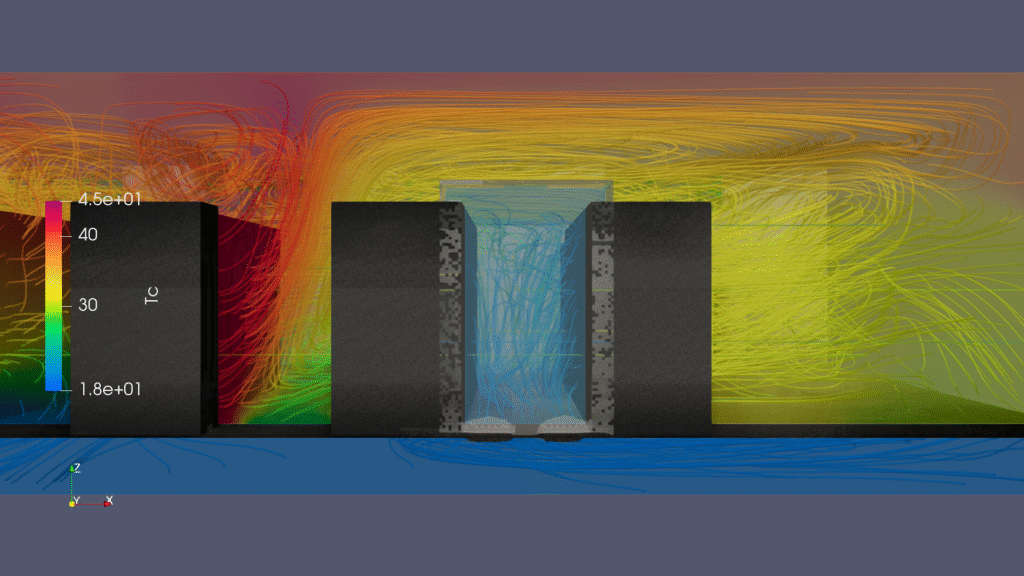

Instead of relying solely on point-based measurements or trial-and-error approaches, CFD provides a continuous, detailed, and three-dimensional view of how air circulates, where heat is concentrated, where cold air is not reaching, and how different configurations can impact the thermal performance of your infrastructure.

This insight allows you to test multiple design alternatives virtually, before implementing them in the real environment. You can verify expected performance without needing to purchase equipment upfront — reducing both implementation and operational costs.

Moreover, CFD enables predictive analysis: it allows you to foresee how your system will behave under future load conditions, helping engineers and facility managers anticipate issues and apply improvements proactively to ensure optimal performance, energy efficiency, and system reliability.

Why does it matter for your Data Center?

Data Centers are highly sensitive to heat. Any failure in thermal distribution can cause air recirculation, resulting in hotspots, reduced equipment lifespan, increased energy consumption, or even the interruption of critical services.

That’s where CFD makes the difference, by allowing you to:

🔍 Identify blind spots in cooling coverage.

💡 Test scenarios without physically modifying the infrastructure.

📊 Deliver visual and numerical data to support design and management decisions.

🌱 Take actions that reduce energy consumption and improve operational efficiency.

This way, your team no longer depends on assumptions or trial and error. You gain the ability to anticipate the impact of any changes to the environment — whether it’s equipment replacement, rack repositioning, or adjusting perforated tiles — and act with precision.

How does a CFD simulation work when applied to a Data Center?

O processo de simulação de um CFD para um Data Center é uma análise complexa de engenharia que exige 3 aspectos The CFD simulation process for a Data Center is a complex engineering analysis that requires three fundamental aspects:

- Professionals with a solid background in Engineering, focused on Fluid Mechanics, Heat Transfer, Applied Mathematics, Programming, and High-Performance Computational Systems.

- A robust numerical simulation software based on finite element or finite volume methods, such as OpenFOAM, Ansys, or Abaqus.

- Sufficient computational resources capable of subdividing the environment into a highly refined mesh and solving the mathematical model in the shortest time possible.

KasiFlow brings together deep engineering expertise, using the OpenFOAM simulation platform along with both local and remote computational infrastructure, enabling the resolution of multiple simulations within a few hours.

The OpenFOAM software used by KasiFlow is one of the most robust and reliable CFD platforms in the world, allowing the development of customized models for Data Centers and other engineering applications — fully adapted to the specific characteristics of each facility.

Expected Impact on Your Operation

Managers who use CFD in the operation of their Data Centers are able to:

- Reduce the risk of IT equipment shutdowns due to overheating.

- Lower energy consumption for cooling.

- Avoid unnecessary investments in new infrastructure.

- Make data-driven decisions supported by visual forecasts.

Other Applications: Assessment of Additional Systems and Equipment

Thermal intelligence via CFD can — and should — be applied to other essential infrastructure components that involve internal heat exchange or heat rejection to the external environment. In both cases, a deep thermal analysis using CFD can optimize thermal interactions, improving the efficiency and reliability of the systems.

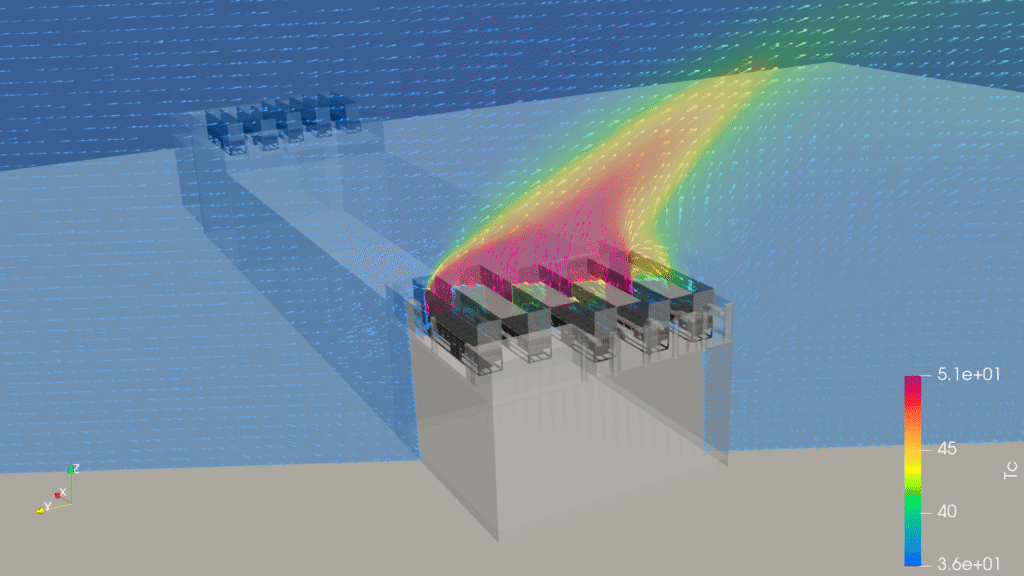

1. Cooling Towers and Chillers in Outdoor Areas

Cooling towers and chillers are critical elements for maintaining thermal balance in operations, especially in facilities operating under high thermal loads. In such cases, the challenge is not just the specification of the equipment, but how the air moves around them.

With CFD simulations, we can analyze and improve:

- Hot air recirculation around poorly positioned chillers

- Impact of architectural barriers or walls that block the efficient dissipation of heated air

- Thermal interference between multiple units operating in parallel

- Effect of wind direction and velocity on the performance of heat exchangers

- Expected improvements through the use of engineered barriers, air channels, and/or auxiliary fans

This type of analysis enables:

- Better placement of new equipment

- Reduction in the intake air temperature, resulting in higher efficiency and lower energy consumption

- Mitigation of overheating risks in open environments, helping avoid shutdowns that could lead to downtime for the entire facility

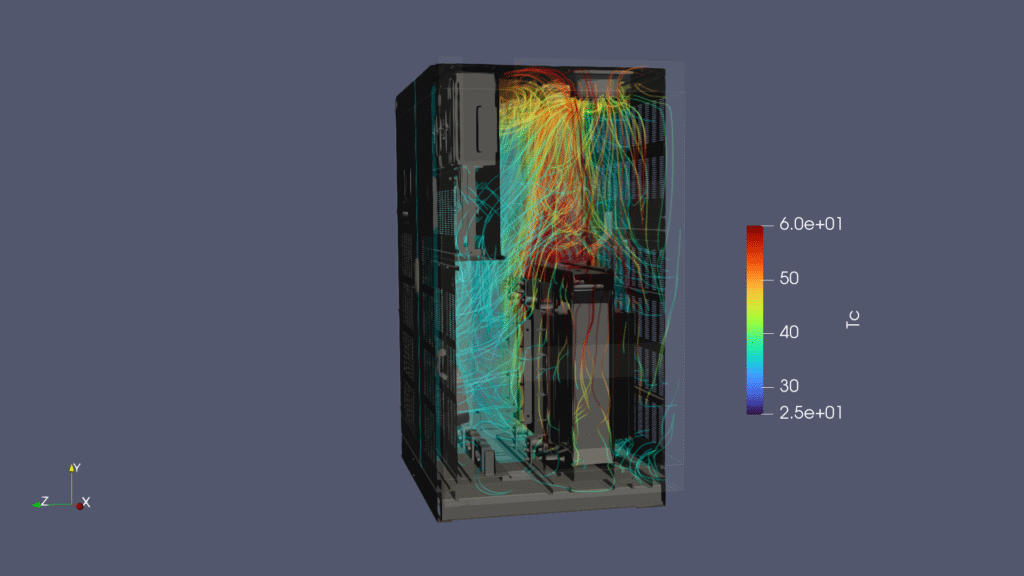

2. Optimization of Heat Sinks and Internal Ventilation Systems

Many electronic or industrial devices rely on internal ventilation systems — such as heat sinks in racks, electronic enclosures, inverters, and electrical panels — which also benefit greatly from CFD analysis.

Through internal simulations of small enclosures, we can:

- Identify heat accumulation zones that might not be detected by standard sensors

- Assess the actual performance of heat sinks and fans under different operating conditions

- Propose geometry or forced ventilation adjustments to reduce hotspots and extend component lifespan

- Validate thermal design innovations, such as cross ventilation, passive heat sinks, or internal airflow channels

An Integrated View of Thermal Management

By applying CFD in an integrated way — both to internal environments and to auxiliary systems and electronic components — KasiFlow provides a comprehensive view of thermal efficiency across your entire ecosystem. This allows for more informed decisions, reduces bottlenecks, and ensures long-term efficiency and system reliability.

Conclusion: CFD is Applied Thermal Intelligence

When you apply CFD, you turn your Data Center into a living, predictable, and optimized system. KasiFlow connects this intelligence with automated analysis and expert consulting, empowering you to make precise, sustainable, and confident decisions.

Whether in your Data Center, near chillers, or inside equipment,

KasiFlow’s CFD reveals the invisible.

It’s with this vision that we guide you to trust the flow and act with precision.